On Friday October 20, 2023, the Chinese government announced stricter rules on the export of certain categories of graphite. In particular, this will have a potentially negative impact on the supply of anode-grade graphite for the production of lithium-ion batteries (“LIBs”).

LIBs are the batteries propelling most electric vehicles (“EVs”). Government regulations and consumer pressure have resulted in strong demand for EVs, but demand is projected to accelerate significantly, with more than 30 million EVs projected to be sold annually by 2030 and over 45 million new EVs annually by 2045.

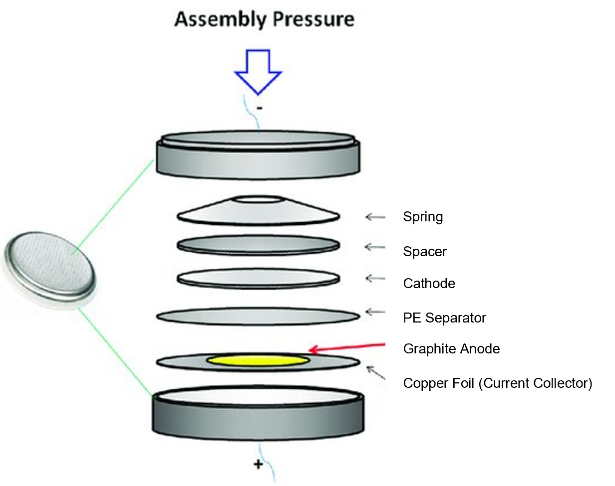

While much attention recently has gone to lithium, as Figure 1 below shows, graphite, by weight, actually is the largest constituent of these batteries. On average, each new EV hitting the roads comes with around 160 lbs of graphite.

Figure 1: Mineral constituents of an LIB

In 2030, if all EVs were to use graphite based anodes, this would equate to some 4.8 million tonnes of anode-quality graphite needed. For 2045 this number goes up to 7.2 million tonnes. With global graphite production at in 2022 standing at ~1.3 million tonnes, it is clear that new mines are needed to meet projected demand. Figure 2 below shows projected shortage in graphite supply, and Benchmark Source, a major supply chain consultancy and research firm, projects that 97 new graphite mines are needed to meet demand.

Figure 2: anode-quality graphite supply shortage projection

Putting this into context of the news out of China, currently 61% of global graphite mining production is located there. Furthermore, with 90% market share, China also dominates processing of anode-quality graphite. So with China potentially clamping down on anode-quality graphite exports, the LIB supply chain may well become compromised.

However, this announcement did not surprise too many industry insiders. Governments around the world have increasingly designated a host of minerals as critical. In the U.S., the Inflation Reduction Act requires 40% of critical minerals in US-made EV batteries to come from US miners, recycling plants, or mines in countries that have free trade agreements with the US (increasing by 10% per year, to a maximum of 80% in 2027). The Canadian government, in its latest budget, has earmarked some $80 billion to support the transition to clean energy, which includes significant support towards securing the supply of critical minerals.

With billions being invested in the development of LIB battery plants in North America, commercial activity has increased sharply over the past year, with both battery and car manufacturers scrambling to secure supply.

Capital Markets Waking Up to the Opportunity?

While the capital markets have not been entirely oblivious to the impact the EV revolution has on critical minerals, this was mainly reflected by frothy activity around lithium, which due to a sharp price increase drew most of the attention.

The combination of a heavy investment in new battery plants, supply of critical minerals being short of projections, and rising political tension, has generated the perfect storm for graphite. While markets have been fairly apathetic to graphite related news, the China development finally woke up investors. We will have to see how sustainable this momentum is, but economically, graphite will do very well, or so everyone says. It is just a matter of time before the capital markets recognize that, and we believe that we may have witnessed the inflection point in the market.

Green Battery Minerals

We are a Canadian company focused on the development of our Berkwood graphite property in Quebec. The property is regarded one of the best prospects globally to produce anode-quality graphite for LIBs.

The Berkwood property is regarded as exceptional for several compelling reasons:

- Location: the project is adjacent to Nouveau Monde’s (“NM”) graphite property, and we believe benefits from the same geological structures. The NM property has been fully explored and on the back of that a PEA was produced, showing an NPV of around $3.6 billion.

- On surface mineralization: much of the exploration work done by the Company has identified considerable graphite quantities at surface. While the Company has yet to produce its PEA, the large number of at-surface finds indicate relatively little complexity for when GEM moves into mine development and production, thereby signaling the potential for relatively low-cost operations.

- Logistics: the project, accessible by road, benefits from close proximity to infrastructure, including major motorways, ports and railways.

- Anode-Quality Graphite: Considerable exploration work done to date, shows that the Berkwood property benefits from a high content of large and jumbo-sized graphite flakes (see Figure 3 below), which is the ideal form for anode production.

- Low-cost clean energy: located in Quebec, GEM has access to abundant low cost, green (from hydro) energy.

Figure 3: Berkwood Graphite Composition Ideal for Anode Production

Green Credentials

With environmental concerns driving the adoption of EVs, increased scrutiny has fallen on the EV supply chain. Currently, the dominant processing method for graphite produces significant harmful effluent.

GEM is currently working with Volt Carbon on the upscaling of Volt’s proprietary dry (air-based) separation technology. The key benefits of this process compared to traditional processing are that the process:

- does not use water, eliminating a significant amount of waste, traditionally associated with the purification of graphite, due to its solventless and reagent-less nature;

- does not produce an effluent; and

- results in the retention of the original quality of the graphite flakes (large +50 mesh and jumbo +35 mesh sized flakes).

We have spoken with several car manufacturers sourcing potential suppliers, and green credentials have become increasingly important in their selection process. With greenwashing (the making of false/misleading claims as to the ‘green’ nature of a company’s products and services) coming under increasing scrutiny, being able to substantiate and quantify the greening up of the supply chain will provide a marked competitive advantage. While this technology is yet to be scaled up to commercial scale, it provides the Company with significant differentiation from its peers, and strengthens its position with potential customers. Finally, the technology, if successfully scaled up, promises a significant reduction in operating costs, further strengthening GEM’s competitive position.

Beyond this technology, GEM’s further green credentials relate to its project being road accessible project , meaning less disruption if mined; at surface graphite produces less waste rock; and finally the company, as mentioned, has access to abundant clean, green, renewable and affordable hydroelectric power.

Innovation

While graphite is the anode material of choice, a derivative, graphene, holds even bigger promise in making batteries better, as explained in Figure 4 below:

GEM and its UK technology partner (Graphene Star: www.graphene-star.com) have used graphite from the Company’s Berkwood property to develop prototype batteries based on graphene. As research progresses, the companies will explore the commercial viability of graphene production for battery anodes.

Conclusion

The EV revolution is projected to cause significant shortfalls in the supply of critical minerals such as graphite. China’s more stringent export controls on anode-quality graphite appear to have woken up the capital markets to the necessity for ‘domestic’ production, as reflected in increased liquidity and valuation of North American graphite companies.

Green Battery Minerals is positioned exceptionally well to capitalize on this opportunity through the development of its Berkwood property, which benefits from a high concentration of anode-quality graphite.

The Company, through its technology partnerships, has the potential for significant competitive differentiation. Innovation focused on cleaning up the purification and processing of graphite, delivers important differentiation that is resonating with potential customers, The production of graphene from its Berkwood graphite for next gen LIBs has the potential of giving the Company a highly disruptive product that is expected to command a significant premium.

The news from China, while disconcerting as it points at increasing international political tension, may have finally woken up the capital markets as to the critical importance of graphite for the North American battery and EV space. The Canadian graphite companies are well positioned to benefit from this dynamic.

As the Company continues towards the delivery of a PEA on its Berkwood property, management is confident of converting what was a mere promise when the team commenced exploring some 8 years ago, into a high-growth, high-value reality. I look forward to reporting to you frequently on our progress.

Thomas Yingling

CEO

Green Battery Minerals

www.greenbatteryminerals.com